TM 10-5411-207-14

3-9. General Repair Procedures (cont).

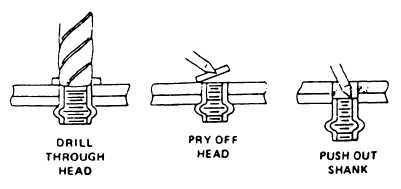

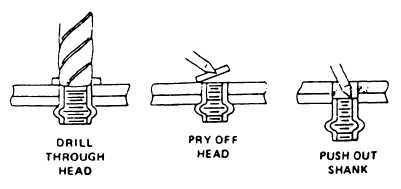

(2) Removal. (Figure 3-8)

WARNING

Drilling creates metal chips which may enter eyes and cause serious

injury. Eye protection is required.

(a) Drill through head of rivnut, using same size drill used to make original

hole. Counterbore in rivnut will act as a drill guide.

(b) Remove head of rivnut.

Figure 3-8. Removing Rivnuts.

CAUTION

Do not puncture opposite face sheet of panel when punching out

rivnut shank.

(c) Punch out shank of rivnut, using a pin punch slightly smaller than hole in

structure. Punch only enough to disengage. Move rivnut aside to install

new rivnut.

(3) Repair. (Figure 3-9) When excessive torque is applied on screws attached on

rivnuts, it may cause a rivnut to turn (spin). Table 3–4 provide the maximum

torque requirement for hardware to prevent rivnut turning. To correct a turning

rivnut, proceed as follows:

(a) Drill a .062 (+.003, -.001) diameter hole by 1.00 inch long on the stem of

the turning rivnut as shown in Figure 3-9.

(b) Install a headless straight pin (Item 25, Appendix D) in hole.

3-15