TM 10-5411-207-14

3-28.

Touch-up Painting. When required, to prevent rust and corrosion, touch up small

areas of damaged or chipped paint in accordance with TM 43–0139. If large areas need

repainting, notify higher level of maintenance.

Section VI. PREPARATION FOR SHIPMENT AND STORAGE

Subject

Para

Page

General

3-29

3-61

Loading Shelter on a Truck or Rail Car. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-30

3-61

Storing Shelter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

3-61

3-29.

General. All items placed inside the shelter must be secured to prevent damage from

shock or vibration during transport. The packaging, bracing, cushioning and tie-down method

employed must be done so it will not allow damage to wall covering and equipment. Make sure

the correct sling assembly is available and in good condition, the skids are in good condition and

securely mounted to the shelter, and the drain plug is loosened for air or rail transport.

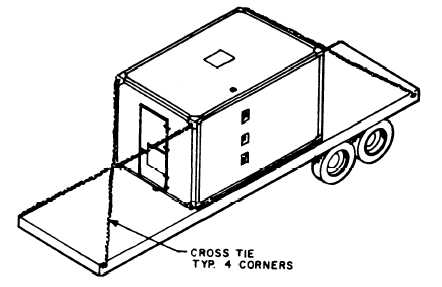

3-30.

Loading Shelter on a Truck or Rail Car. The shelter with its payload is capable of

being transported by commercial cargo vehicle or any standard 40-foot flatcar as used in the

continental United States. During vehicular transport, the shelter should be secured as shown in

Figure 3-32. During rail transport, the shelter shall be blocked and braced to avoid shifting on

flatcar (Figure 3-33). The loaded shelter is capable of withstanding humping speeds of nine

miles per hour with no permanent deformation.

3-31.

Storing Shelter. Accumulation of moisture within the shelter resulting from

temperature and humidity fluctuations can damage equipment. Minimize moisture accumulation

by keeping shelter doors, louver covers, and drain holes open during indoor storage. During

outdoor storage, keep doors and drain holes closed, but keep louver covers open.

Figure 3-32. Truck Tiedown.

Change 1

3-61