TM 10-5411-206-14

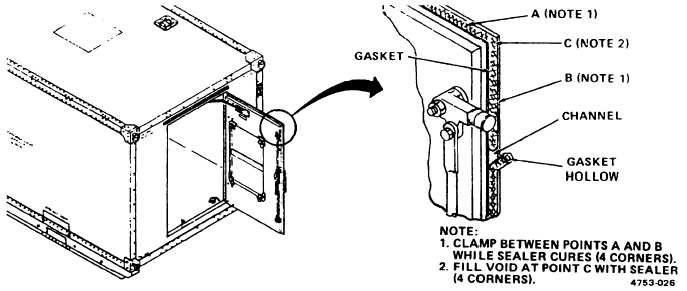

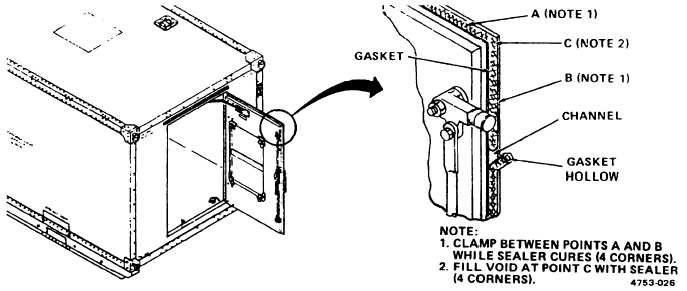

4-12. Weather Gaskets (cont).

(6)

(7)

(8)

Allow adhesive to cure at least 12 hours at 50% RH and 70°F (21°C). Lower humidity and temperatures

require a longer cure time.

After adhesive has cured, fill gasket channel voids at each corner with adhesive so that it is flush with

door. Bond gasket ends together with adhesive to form a tight joint. Do not fill gasket hollow section at

joint.

Test gasket seating by inserting a piece of paper 0.005 inch (maximum) thick by 2-1/2 inches wide at

center of top and bottom of door or cover and three places along each side. When door or cover is

closed, paper should be trapped between weather gasket and mating surface (but not under RFI/EMI

gasket in shielded shelters). If paper can be withdrawn without any resistance while door or cover is

closed, gasket is not making good contact with mating surface. Correct as follows:

(a)

(b)

(c)

(d)

Check condition of gasket. Replace gasket if it is in unsatisfactory condition, or if it is improperly

installed (kinked or poorly spliced).

If gasket is in good condition, gasket compression maybe increased by changing thickness of latch

keeper shims (para 3-15) or hinge shims (para 4-17). Make sure latches contact their respective

keepers when closed.

After adjustments are made, make sure door cover is capable of opening and closing fully without

binding.

Repeat gasket seating test.

Figure 4-4. Weather Gasket Replacement.

4-10